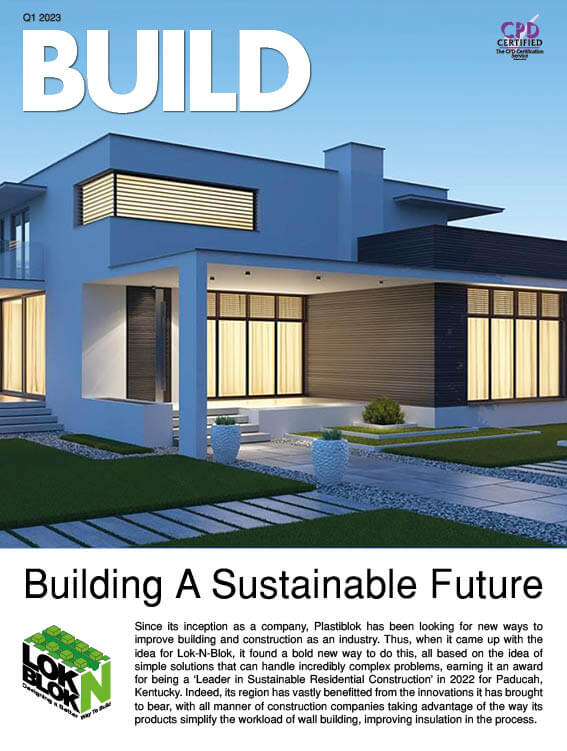

Efficiency is the king of manufacturing. Because of this, it frequently serves as a model for other industries to follow as they work to increase efficiency and cut down on waste. One industry that can benefit from the principles of lean manufacturing is construction. The rise in material costs, with building materials costing 25% more in 2022 than they did in 2021, has made minimising waste and cutting costs top priorities in the construction industry. This is where lean manufacturing principles can help.

Lean manufacturing, also known as lean production, is a systematic approach to minimising waste and maximising value in the manufacturing process. It involves organising the workspace, streamlining processes, and constantly improving through the use of tools like Kaizen and Six Sigma. The approach has been widely adopted in manufacturing, but its principles can also be applied to the construction industry.

Lean manufacturing and modular building are bridging the skills gap in the construction sector. Off-site manufacturing and modular construction are becoming increasingly popular as a way to build structures more efficiently, reducing waste and cost, and achieving sustainability targets. This approach is particularly useful in areas where there is a shortage of skilled labour. By applying lean manufacturing principles, companies can improve the efficiency and productivity of their workers, while reducing costs and increasing quality. Now is the perfect time for lean manufacturing to gain traction in the construction industry, as we’re all pushed to deliver more with fewer resources and shorter time frames. One of the key principles of lean manufacturing is the 5S approach of organising spaces, which stands for sort, set in order, shine, standardised, and sustain. This approach can be used to determine the value of each stage and phase, ensuring that products are produced to a continuously higher level.

Modular construction and lean manufacturing have already proven to be successful when used together. For example, Premier Modular, a UK-based construction company, used the skills of experts in lean manufacturing to improve the procedures in its facilities. By adopting lean manufacturing principles, they transformed beyond recognition, using lean manufacturing flow lines, Kanban systems, and the Kaizen technique to improve the quality of what is produced. The Kaizen approach’s cyclical nature makes lean manufacturing never stop improving efficiency.

The advantages of the 5S system and lean manufacturing, which were first utilised in the automobile industry, have prompted firms all over the world to embrace these techniques. Standardised componentry in offsite manufacturing makes output reproducible, increasing efficiency by ensuring uniformity in assembly. Premier observed time savings and increased output year over year, cutting the build time for retail clients by 25% and passing along sizable cost savings to the client.

The advantages of lean manufacturing techniques used in modular and offsite construction provide a number of additional benefits. One is consistency. The core of lean manufacturing is a consistent methodology, creating a higher quality product, leading to faster handover and reducing the likelihood of aftercare defects. This helps to build relationships with supply chain partners. The total safety of operations is increased as working procedures are outlined as standard procedures. Because of these production procedures, operational safety is continuously enhanced, just like with product quality.

Many sectors can benefit from this approach, including the education sector. The 5S approach can all help schools, colleges, and universities to reduce waste, increase efficiency, and ensure a consistent methodology for construction projects such as temporary classrooms. Applying lean manufacturing principles can help educational institutions to build more efficiently, reduce waste, and increase productivity, ultimately leading to better learning outcomes for students.

Other industries would be making a big mistake if they ignored how lean manufacturing concepts could benefit them. Lean manufacturing helps to handle a number of difficulties in the business, such as rising costs, safety concerns, skills shortages, and sustainability targets. Its principles benefit not only construction but also other industries. The advantages of lean manufacturing will continue to be identified and implemented as best practice, advancing and extending throughout traditional construction and other industries.