Power tools are used in construction projects. They’re fast and efficient. But the reality is that

they break down just like any other tool. The carbon brushes inside the motor can also

malfunction, leaving unfinished tasks. Here are ways to tell if your power tool carbon brushes

need replacement.

Carbon Brushes Causing Poor Performance

An operator accustomed to using a power tool would know if it’s in good condition or if the

device is functioning poorly. In general, one would link it to malfunctioning components, as an

overused carbon brush can impact the power tool’s overall performance.

If you look at your power tool, you may notice that it may need maintenance because of the

debris and dirt. The dirt can find its way to the carbon brush area, gradually eroding the carbon

brush. You can look into sources like Top Deals Online, where you can find quality information

about carbon brushes immediately.

The carbon brush must connect to the armature commutator to keep the flow of current steady

and the motor running. If the carbon brush continues to erode, the connection stops, and the

brushes cannot power the motor of the power tool anymore.

The interrupted current manifests in low power. Even if it’s plugged into a wall socket/, the

power tool becomes useless because of the disconnection inside. It also won't be able to turn its

maximum turns per minute needed to accomplish the job.

The Power Tool Sparks

Some power tools may spark due to friction, like when an angle glider is used on a material. A

spark is a sign of a problem when it’s coming from the inside of the electrical tool. It could mean

that the carbon brush has reached its end.

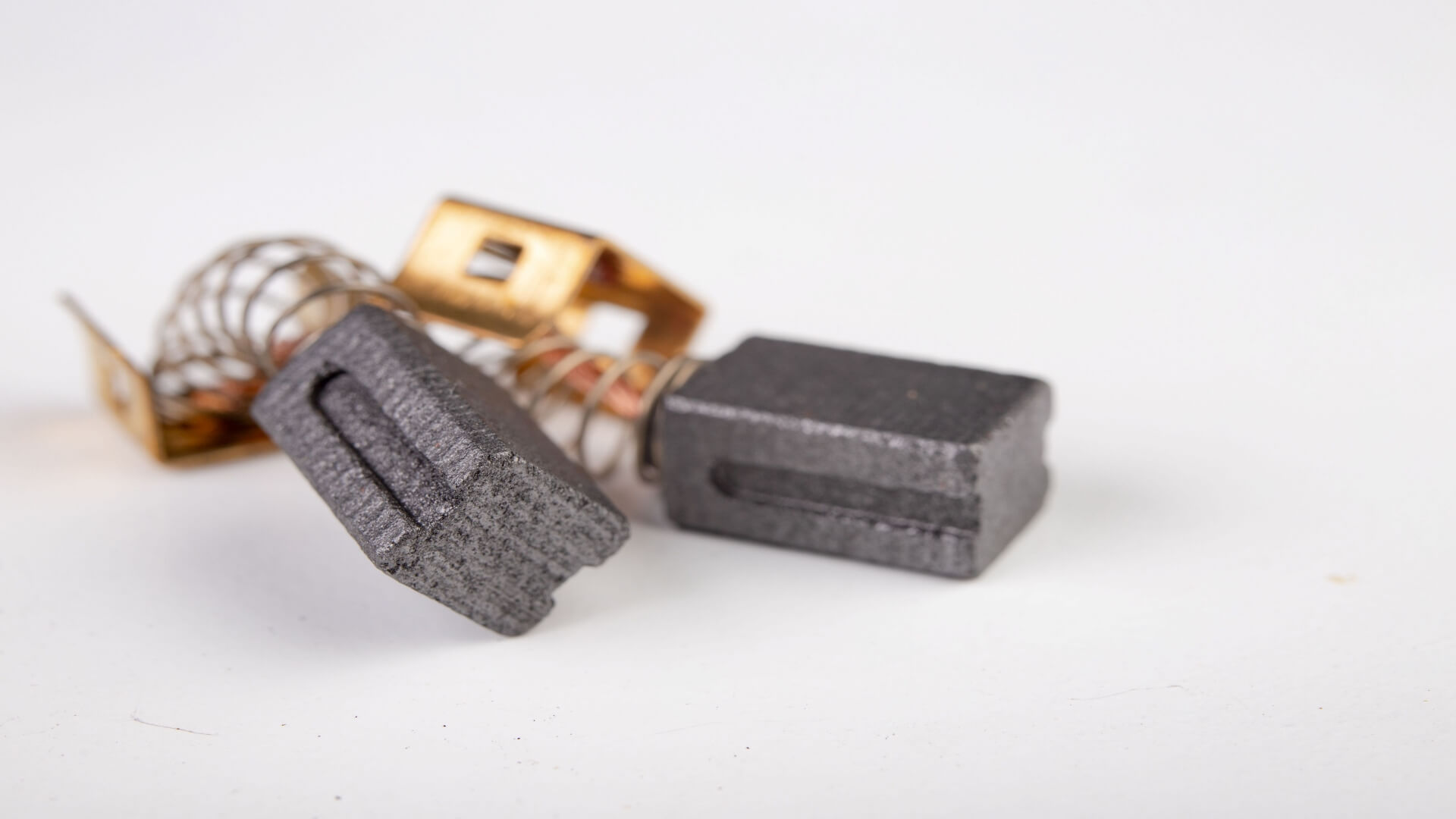

Carbon brushes are small and thin parts that connect electrical currents within the motor. Sparks

are caused because the tool cannot correctly conduct electricity anymore. The scattering sparks

eventually block the air ventilation of the power tools. To avoid electrical shock and fire hazards,

sparking carbon brushes must be immediately replaced.

The Power Tool Produces Strange Noises

You’re using the power tool the way you typically do, and it starts making strange noises. A

banging noise is common for power tools that have malfunctioning carbon brushes. The

component could be stuck in the commutator slots and cause a banging noise because of the

armature that keeps spinning. When it bounces off the commutator, that also causes loud

thumping.

When a power tool starts making an unusual noise, either the carbon brush or other parts are

loose of broken. It tells the user to stop using and unplug the power tool. The carbon brush might

need replacement. Ignoring the sound can further damage the tool.

Deformed carbon brushed will bounce on the commutator while the armature spins. It’s

inevitable also to hit nearby parts and make a sound that shows it’s not in good working

condition.

The Power Tool Becomes Shaky

Normal working power tools can turn on smoothly without shaking. But sometimes, they start

working when you need to give it a light tap, knock, or kick. If you have to do these, your carbon

brush might be broken.

There’ll be an incomplete current connection if the carbon brush becomes stuck in its channel

and needs to connect to the armature properly. The carbon brush must complete the circuit for

the power tool to restart. The user may have to give the power tool a light tap to gently force the

carbon brush to connect with the armature to power up the tool.

If the problem persists, you’ll need to replace the carbon brush to use the tool continuously.

You Can Smell Something Burning

Power tools run on motors that constantly rotate and produce heat. Anything that uses electricity

will generate heat. That’s also the case when friction occurs from any of the components. But it’

unusual if the device begins producing a burning smell after a few seconds to minutes while

operating the tool.

When carbon brushes are overused, they’ll create a smell along with some smoke or sparks.

Once you smell something burning from the power tool, please turn it off and unplug it from the

power source. Inspect it, as it may need a carbon brush replacement.

In Conclusion

Carbon brushes are small components responsible for conducting current between the moving

and unmoving parts of the motor. You’ll need to replace it when it smells and produces sparks.

The tips above will tell you when carbon brushes need replacement.