Gather ’round and let’s chat about the construction world’s rising star: CNC machining. This isn’t just some trendy fad; we’re talking about a full-blown revolution in how we build stuff.

From skyscrapers to your buddy’s new deck, these high-tech tools are slicing through materials like butter and spitting out parts that fit together tighter than puzzle pieces. So what’s the big deal? Hang tight, because we’re about to break down why CNC machining is becoming as essential to modern construction as hard hats and steel-toed boots on a building site.

What is CNC (Computer Numerical Control) Machining?

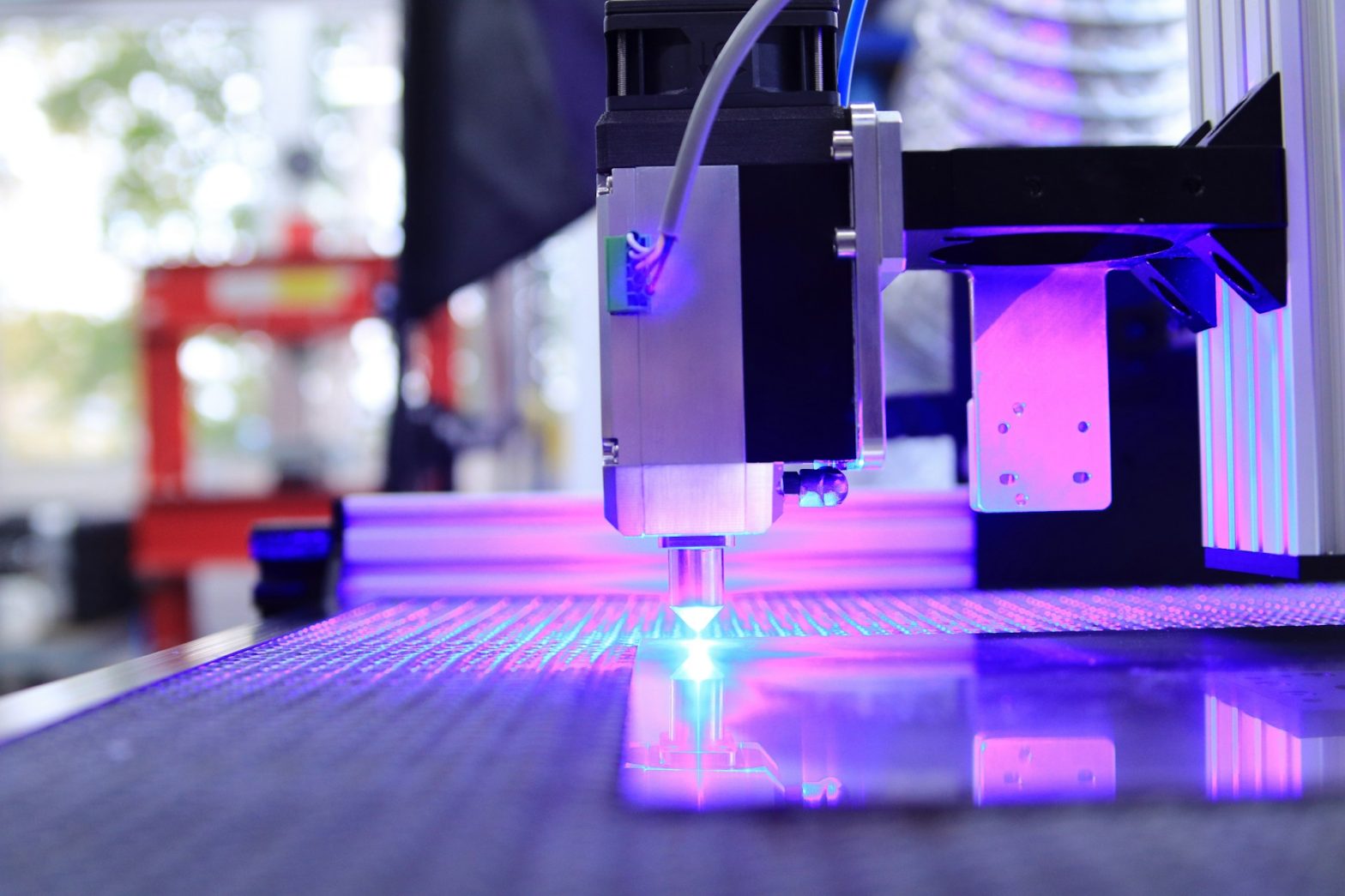

CNC machining is the process of automating or partially automating tasks that manufacturers typically had to do manually in the past, like creating parts or conducting maintenance.

You’ve probably seen the flashy posts on manufacturers’ social media marketing, touting the next big thing in efficiency. Well, buckle up because CNC machining isn’t just hype. It’s a bona fide wallet-friendly revolution for the construction industry that isn’t going away anytime soon.

This tech is like your frugal friend who knows all the best deals—trimming down those pesky labor costs by automating tasks and letting machines tackle the grunt work. The result? Your employees can focus on more skilled aspects of their jobs without clocking in tons of overtime.

5 Reasons Why CNC Machining is Growing in Popularity

Strap in, and let’s explore the top 5 reasons why CNC machining is swiftly becoming the MVP in the construction industry. Spoiler alert: it’s revolutionizing the game big time!

1. CNC Machining Reduces Labor Costs

Picture this: a bustling construction site where the hum of CNC machines fills the air, chiseling away at materials with zero complaints or coffee breaks. This isn’t just about automation for automation’s sake. It’s about financially savvy moves that cut labor costs with robotic precision.

By shouldering the mundane tasks, CNC tech allows your crew to dive into more complex gigs without piling up overtime hours. Fewer hands-on repetitive jobs mean leaner payroll expenses and beefier profits. In short, these mechanized maestros are superheroes, saving your budget.

2. CNC Machining Creates Uniformed Products

Ever found yourself in the middle of a construction project, crossing your fingers that each piece fits like it’s supposed to? Enter CNC machining—this tech is all about delivering dead-on consistency. The level of uniformity is nuts; every product is a spitting image of the last.

We’re talking about spot-on replicas every time. For anyone who’s spent hours eyeballing measurements and sweating over variances, this level playing field where everything matches up just so is nothing short of a beautiful symphony in motion. It’s precision on repeat!

3. CNC Machining Improves Labor Safety

Ever notice how milling machines seem like obstacle courses? Well, cue the CNC machines, and we’re ushering in an era of zen-like safety. By automating all things risky, those tasks that had workers playing tag with danger are now chillin’ in the metal paws of these beasts.

It’s a win-win: employees dodge injury more than Neo dodges bullets, and job sites start feeling less like ‘Final Destination’ sets for your appendages. Translation? Less time fretting over band-aids and worker’s comp forms, more time crushing that project timeline safely.

4. CNC Machining Provides Machine Monitoring

Keeping an eye on machinery is about as exciting as watching paint dry. But lo and behold, CNC machining steps in with its high-tech optics to change the game. This isn’t your grandpa’s idea of monitoring. It’s more like having a 24/7 digital watchdog that doesn’t miss a trick.

Breakdowns? Errors? So last century! With real-time data and predictive maintenance throwing up big red flags before trouble hits, you’re cruising down Easy Street with fewer speed bumps. It’s like adding extra layers of bulletproof glass to your own business operations.

5. CNC Machining Offers Ultimate Flexibility

Imagine a world where your construction materials can be any shape or size at the push of a button. That’s not science fiction—it’s a delicious reality with CNC machining. Need to switch up designs? Easy peasy. These versatile workhorses are like high-tech chameleons.

They can adapt on the fly to whatever wild design specs you throw their way. Small batches, custom pieces, intricate patterns—nothing fazes them. It’s like having an omnipotent construction genie in your toolkit. Just whisper your wishes into the software, and presto!

In Conclusion…

Alright, future builders and industry shapers, there you have it—the lowdown on how CNC machining is crushing it in the construction game. If this tech-savvy approach speaks to your inner innovator, don’t just sit there dazzled by shiny machinery—embrace it!