In residential construction, the garage door is far more than a simple access panel — it functions as a critical part of the building envelope. However, failure often results from corrosion, repeated impact, misalignment, neglect of sealing or environmental exposure. The industry must increase garage door durability, but how can that be reconciled with a growing emphasis on sustainability? Can environmentally friendly garage doors also meet the longevity test?

The Durability Challenge in Residential Garage Doors

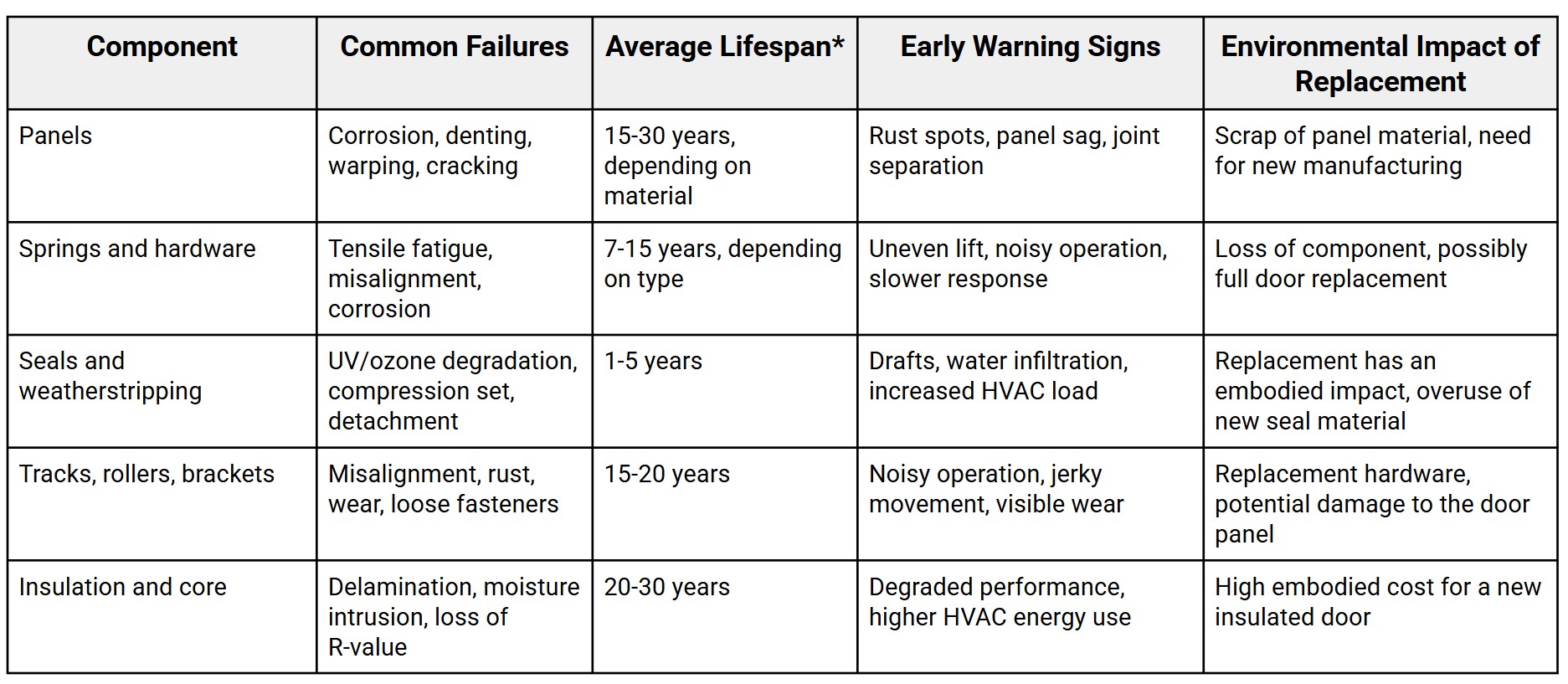

The typical residential garage door lifespan is between 15 and 30 years, but this can be complicated or reduced by multiple factors:

- Material degradation: Metal panels may corrode or rust, wood may warp or rot, and fiberglass may fatigue under UV and thermal cycling.

- Operational wear: Every cycle of opening and closing induces spring tension, panel flex, roller friction and track stress.

- Impact damage: Damage from vehicles or other sources is common.

- Climate-specific challenges: High humidity, salt air, and extreme heat or cold all accelerate wear and degrade seals, hardware and finishes.

- Installation and structural support: If the headframe or tracks are misaligned or the springs are undersized, components wear prematurely.

Together, these stressors create a significant risk of early failure, leading to both financial costs, such as replacement or repair, and environmental costs, including waste and the embodied energy of a new door.

*Lifespan values depend heavily on installation, climate and use.

When a garage door fails, the homeowner incurs both the financial cost of replacement and the environmental cost of embodied materials, transportation and waste. Conversely, choosing longer-life components increases garage door durability, meaning fewer replacements are required. However, manufacturing durable components involves higher upfront resource consumption.

This is the sustainability paradox — longer-lasting components initially use more resources but reduce life cycle environmental impact in the long term.

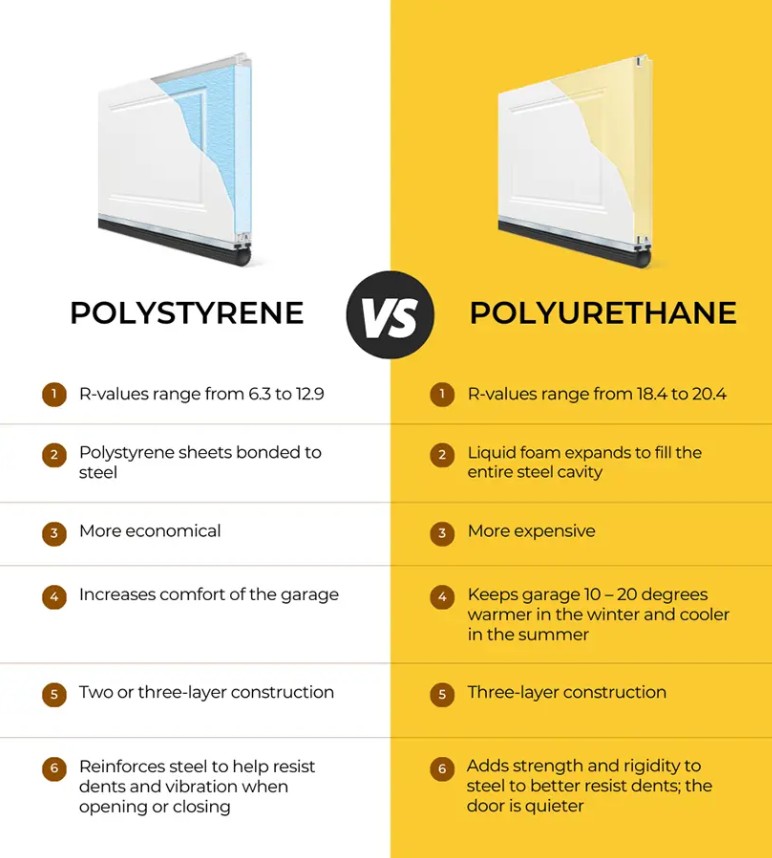

Material Selection: Durability and Environmental Considerations

Material choice is fundamental. Below is a comparative analysis of common long-lasting garage door materials.

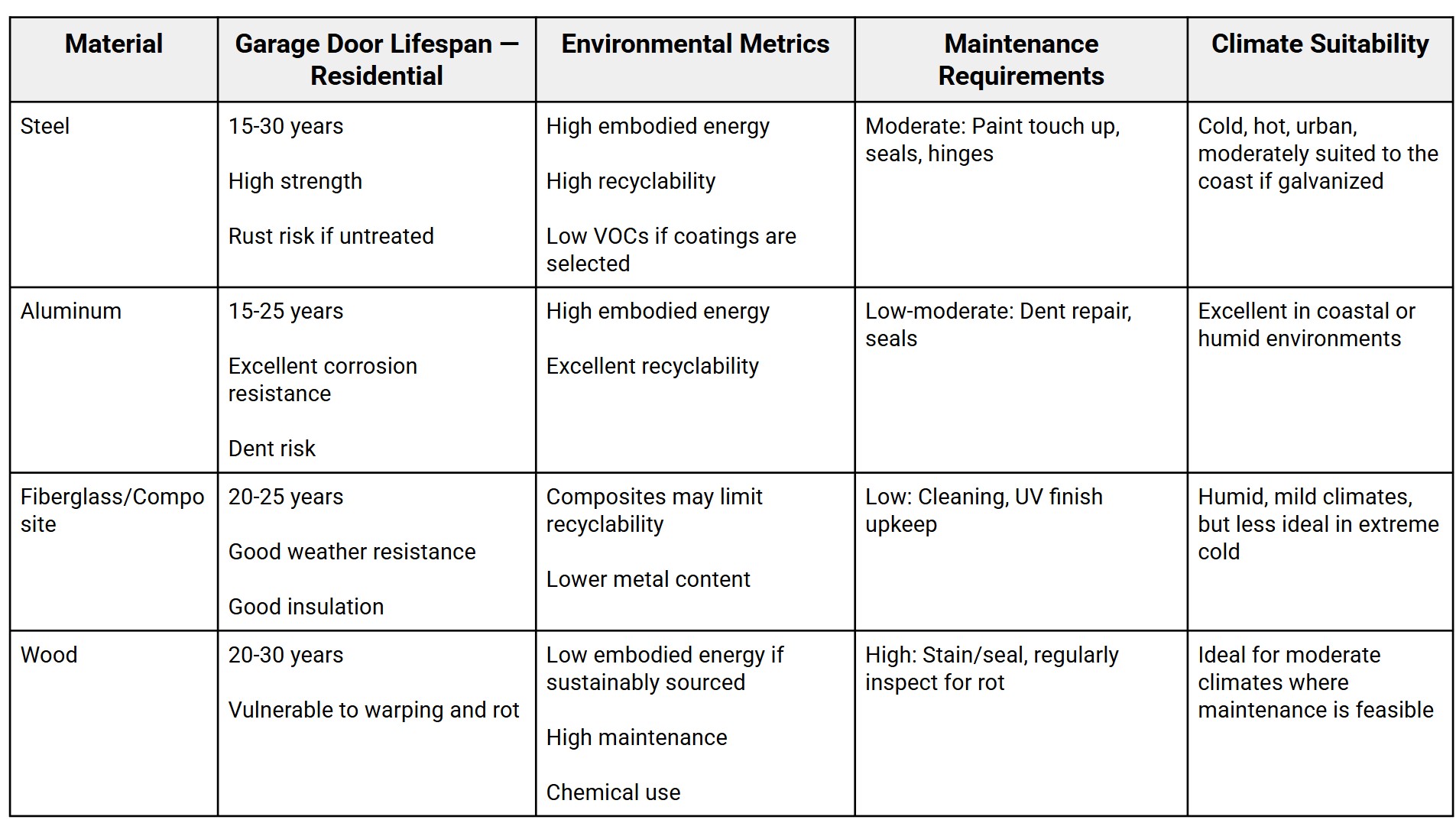

Innovations and Life Cycle Thinking

As material science advances, insulated steel cores with improved urethane create stronger, more efficient doors, which is one way to increase garage door durability. Selecting options with high recycled content, reduced VOC finishes and modular panel replacement rather than full door designs also improves sustainability.

Life cycle assessment (LCA) should be applied when thinking about environmentally friendly garage doors. One that lasts 30 years avoids multiple replacements and therefore reduces waste, embodied materials and resource use over time.

Material choice is only half the battle, however. Even the most long-lasting garage door materials will fail early if installed improperly.

Installation Best Practices for Maximum Durability

Critical installation factors affecting long-term performance include:

- Structural framing and header reinforcement: The door header must resist dynamic loads and support correct track geometry. Any sag or flex in the framing leads to misalignment and accelerated wear.

- Precise track alignment and hardware installation: Tracks, rollers and hinges must be perfectly aligned for smooth cycles. Misalignment causes increased friction, hardware fatigue, noise and reduced lifespan.

- Weather-sealing techniques: A proper peripheral seal blocks air, water and debris ingress, protecting the door’s interior and insulation and reducing thermal stress cycles.

- Drainage: A garage threshold should shed water away from the bottom of the door. Pooling water accelerates corrosion or wood rot at the base of the panel.

- Electrical/openers specification: Correct power supply, surge protection, and compatibility between the door and opener reduce strain. For example, an incorrectly specified opener for a heavy door will cause undue wear.

There are also regional considerations. For coastal or hurricane-prone regions, wind-load requirements must be checked, and reinforcement may be mandated. Moisture management is crucial in humid climates, requiring ventilation or corrosion-resistant hardware. In extreme temperature zones, an insulated door with proper sealing helps to reduce cycles and stress.

This installation quality checklist outlines verification points to ensure maximum durability:

- The header/frame meets the structural load-bearing specification for the door size and wind zone

- Track alignment is within manufacturer tolerance, and roller movement is smooth without binding

- Hardware grade is appropriate for door cycles specified

- Weather-seal is installed continuously at the bottom, sides and header with a threshold configured for drainage

- Electrical amperage is correct, with surge and ground protection and compatibility with the opener

- Fully open/close the door for at least five cycles to observe smoothness, noise and reversal accuracy

- Warranty activation and installation date are recorded

Proper installation pays dividends with fewer repair calls, longer life, full warranty validity and better long-term performance. Installation quality is as important as material quality in determining ultimate durability.

Clopay® and LiftMaster Integration — Engineered Durability Systems

Modern residential garage door systems increasingly pair the door with the opener and controls, recognizing that the system is only as strong as its weakest link. Two brands stand out for their engineered approach — Clopay for doors and LiftMaster for openers.

Clopay’s Approach to Residential Garage Door Durability

Image: Clopay, Modern Steel™ door.

Clopay’s Modern Steel™ collection emphasizes high durability. A rust-prevention multilayer steel panels system includes hot-dipped galvanization, metal oxide pretreatment, and a baked-on primer and topcoat, with the homeowner’s choice of one-, two- or three-layer build.

Intellicore® insulation technology is formulated with polyurethane injected between the steel layers. This is available on nearly all of the company’s doors. These doors are fully compliant with regulations — for example, they contain no hydrofluorocarbon pollutants (HFCs).

Image: Clopay, polyurethane insulation.

Clopay garage door durability is rooted across material, finish, insulation and environmental compliance perspectives.

LiftMaster Opener Systems as Durability Enhancers

Image: Clopay and LiftMaster.

LiftMaster offers residential openers engineered for extended operational life, with durable motors, advanced drive systems, smart home diagnostics and battery backup systems. For example, models feature a smooth start/stop operation to reduce mechanical shock to the door.

Industry commentary emphasizes LiftMaster’s heavy-duty construction and long-term warranties. When properly matched to the door’s weight, cycle frequency and environment, such an opener reduces mechanical stress, prevents misuse and enhances door lifespan.

Pros and Cons of a Clopay-LiftMaster Integrated Garage Door System

Image: Clopay, modern steel door.

The advantages of this integrated system include:

- Engineered durability: A premium door with an advanced finish plus a robust opener equals fewer breakdowns.

- Lower maintenance burden: High-quality materials reduce the need for frequent servicing.

- Sustainability credentials: Clopay’s compliance with environmental standards and its long-life doors reduce life cycle impact.

- System optimization: Opener diagnostics and door durability combine for total system reliability.

Some of the potential drawbacks include:

- Higher upfront cost: Premium materials, insulation and opener tech carry a higher initial investment.

- Installation complexity: To achieve the full benefit, professional installation and correct pairing are required.

- Potential overspecification: Extra cycles may not pay off in low-stress scenarios, such as in low-usage or mild-climate homes.

Overall, it’s clear that Clopay garage door durability is enhanced when paired with LiftMaster openers, good installation and regular maintenance. Clopay’s environmental certifications and manufacturing practices reduce the typical trade-off between durability and sustainability. This integrated approach shows how longer-lasting components need not compromise ecological performance.

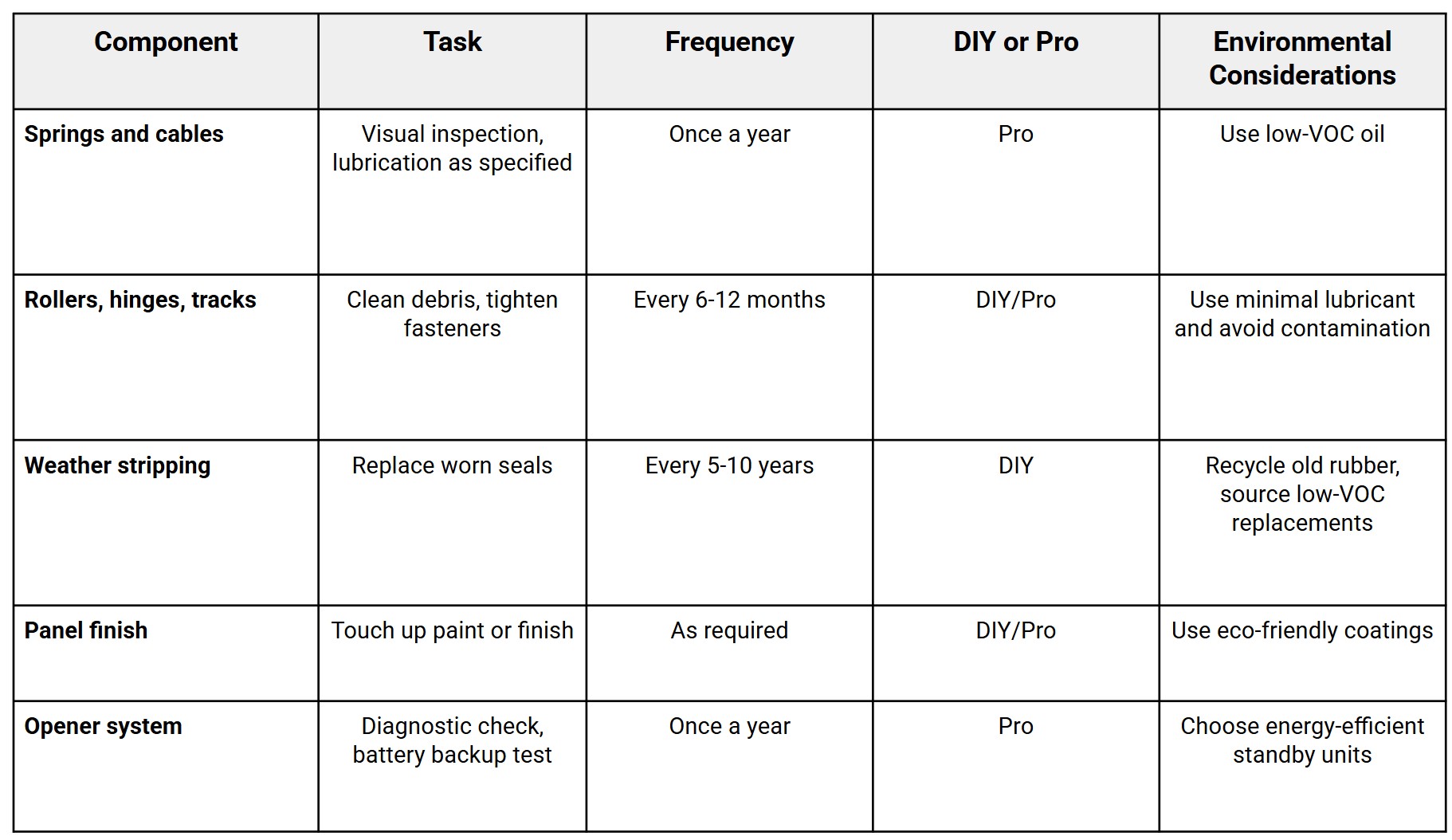

Maintenance Protocols for Extended Garage Door Lifespan

Having selected durable and environmentally friendly materials and with the door professionally installed, the final step is to ensure timely maintenance.

Modern Innovations in Reconciling Durability and Sustainability

The sector is witnessing several promising technologies for future environmentally friendly garage doors with increased durability.

- Bio-based lubricants with extended performance life: These reduce harmful chemical use and reliance on fossil fuels, as well as improve lubrication longevity. This lowers wear and environmental impact.

- Self-healing finishes and coatings: Metallic or polymer finishes can repair minor scratching, extend cosmetic life and reduce repaint cycles.

- Smart monitoring: Door openers, sensors and diagnostics detect misalignment or wear early, enabling preventive maintenance rather than reactive replacement.

- Energy harvesting: Some systems are exploring the capture of mechanical energy from cycles to power sensors or lighting, thereby lowering net energy consumption.

- Modular design: Rather than replacing an entire door, panels, tracks or insulation cores can be replaced, reducing waste and embodied footprint.

- Advances in recyclable and renewable materials: Composite or hybrid doors now use higher recycled content or renewable fibers and are designed for end-of-life recovery.

- Circular economy approaches: Manufacturers now offer panel-return or take-back programs for doors reaching the end of life, recycling components and reducing waste.

Frequently Asked Questions About Garage Door Durability

Here are the answers to some common questions on this topic.

Which Garage Door Materials Require the Least Maintenance While Remaining Environmentally Responsible?

Steel doors with proper corrosion protection strike a strong balance between durability and recyclability. Aluminum is low-maintenance in corrosive environments but is prone to denting. Composite doors may require less upkeep, but end-of-life recycling is less certain.

How Does Insulation Affect Both Energy Efficiency and Durability?

Insulation controls heat transfer, reduces thermal cycling stress and helps the door feel more rigid. Less flex means reduced wear on hardware and seals. Premium doors with insulation therefore support both durability and environmental performance.

How Do LiftMaster Openers Extend the Life of a Clopay Garage Door?

When the door and opener are properly matched, a LiftMaster opener reduces mechanical stress on the door system. That means less fatigue in springs, less wear on tracks and rollers, and fewer unexpected collisions — increasing Clopay garage door durability.

What Are the Most Environmentally Friendly Lubricants for Garage Door Maintenance?

Bio-based or synthetic nonchlorinated lubricants with long lifespans, low VOC content and labeled for use on moving door components are preferred. Avoid heavy greases.

What Weather Conditions Most Severely Impact Garage Door Longevity?

High humidity, salty coastal air, extreme temperature swings, intense UV exposure, heavy snow loads and windstorms all increase deterioration risks. This can happen through corrosion, warping, seal failure, insulation degradation and mechanical overload.

How to Increase Garage Door Durability

Image: Clopay, durable overhead doors.

The key to balancing garage door durability with environmental responsibility is to treat the door system as a long-life building component rather than a short-term commodity. Specify high-quality materials, ensure expert installation, adopt a preventive maintenance regime and consider integrations such as the Clopay-LiftMaster system for optimal lifespan. Investing more upfront in durability and sustainability pays dividends in reduced replacements, lower waste and better building performance.