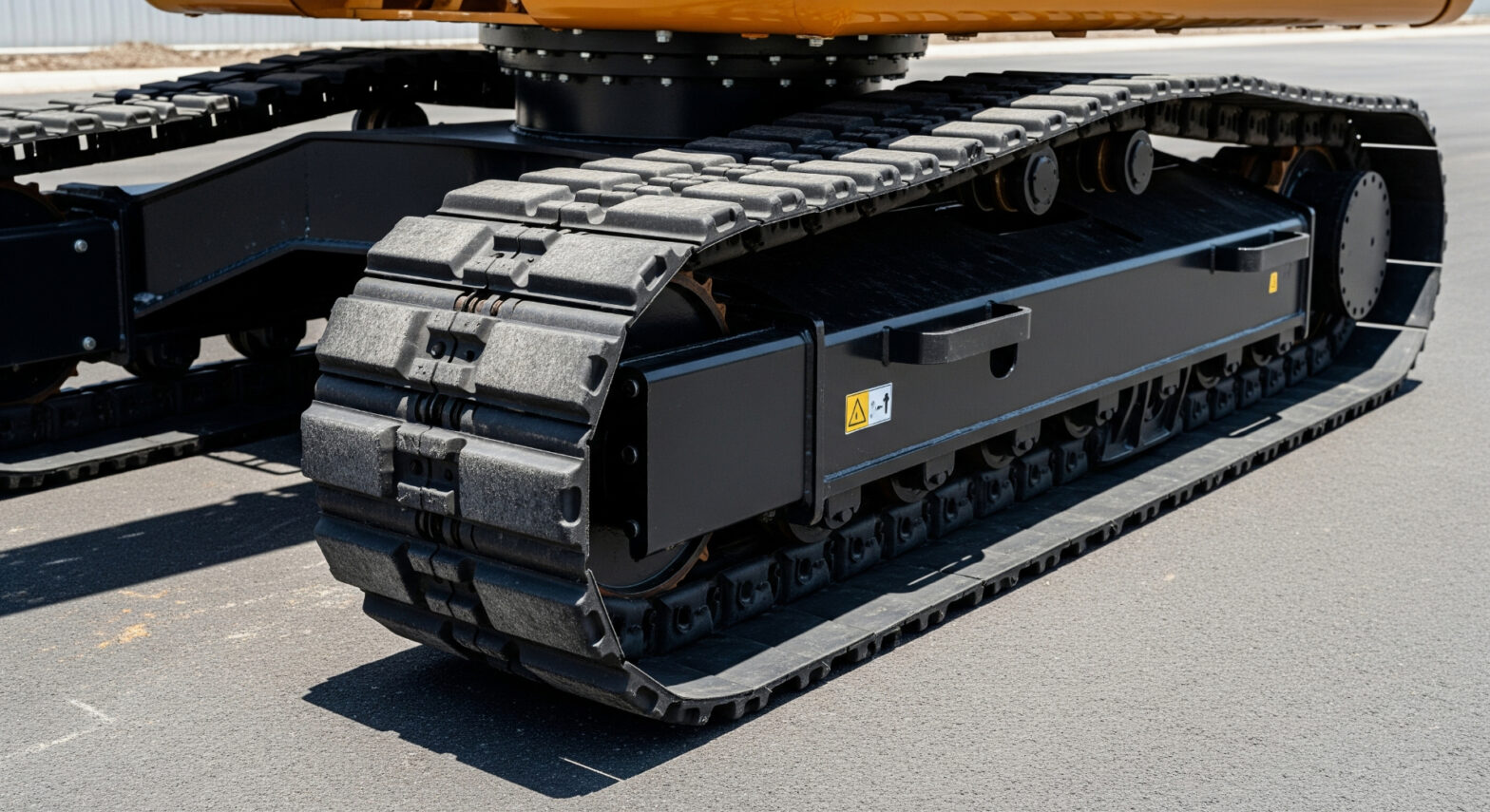

Operating heavy tracked machinery in developed urban areas presents a fundamental conflict: the need for powerful excavation versus the requirement to protect existing surfaces. Standard steel tracks, while essential for traction in rough terrain, can cause significant damage to asphalt, concrete, and turf, leading to costly repairs and project delays.

This challenge is addressed by modern excavator track pads. These are not simple accessories, but highly engineered components that attach to a machine’s steel tracks, enhancing equipment versatility and offering a significant return on investment (ROI). For construction leaders, developers, and project managers, understanding the strategic value of these components is key to improving operational efficiency and risk management in modern construction environments.

Maximizing Asset Value and Operational Efficiency

The primary business case for rubber track pads is the dramatic increase in asset utilization. Equipping a steel-tracked excavator with modular rubber pads transforms it into a multi-role machine capable of operating across varied surfaces. This provides several clear financial and operational benefits:

- Increased Versatility: A single machine can perform heavy digging on dirt (with pads removed) and then transition to work on paved streets or finished landscapes (with pads attached). This reduces the need for multiple specialized machines on a single project.

- Reduced Ancillary Costs: The need for ground protection mats is eliminated, saving significant costs associated with the transport, labor, and materials of these secondary measures.

- Risk Mitigation: Pads prevent costly damage to municipal and private property. The investment in a set of pads is often less than the cost of repairing a single damaged surface, directly reducing project liability.

- Improved Compliance: The rubber’s damping properties significantly reduce noise and vibration. This is critical for complying with local noise ordinances, especially in residential areas, and allows for work during restricted hours, helping to keep projects on schedule.

The Technology Behind the Performance

The effectiveness of a modern track pad is the result of advanced material science and precise manufacturing. The quality and composition of the materials directly impact durability and lifespan.

- Material Compounds: Premium pads utilize scientifically formulated blends of natural and synthetic rubbers. This approach combines the tear resistance of natural rubber with the superior abrasion, temperature, and chemical resistance of synthetic polymers.

- Core Construction: The pad’s structural backbone is an internal steel plate. High-quality pads feature forged steel cores, which are tougher and more resistant to fracture than cheaper cast steel alternatives.

- The Bonding Process: The most critical aspect of construction is the bond between the rubber and the steel core. Reputable manufacturers use a multi-stage process involving chemical bonding agents and high-pressure vulcanization to prevent delamination, which is the most common mode of failure in lower-quality pads.

Selecting the Right System

Selecting the right rubber pad system depends on the project’s needs for flexibility and durability.

Bolt-On

- Requires pre-drilled holes in the steel grousers.

- Long-term or semi-permanent use on dedicated machines.

Clip-On

- Clamps onto standard grousers with no modification needed.

- Projects requiring frequent switches between dirt and paved surfaces.

A Strategic Approach to Procurement

The market offers a wide spectrum of quality and price, from Original Equipment Manufacturer (OEM) parts to a diverse aftermarket. A strategic procurement plan focuses on Total Cost of Ownership (TCO), not just initial price.

- OEM Parts: The highest quality and cost, ideal for new machines under warranty or for mission-critical applications where a perfect fit is guaranteed.

- Premium Aftermarket: This tier offers the best balance of cost and quality for most fleets. Reputable aftermarket suppliers provide parts that often meet or exceed OEM specifications at a lower price point.

- Budget Aftermarket: The lowest initial cost comes with a higher risk of premature failure and inconsistent quality. This option is best reserved for low-hour, non-critical applications.

The Future is Smarter and More Sustainable

Innovation in this sector is accelerating, aligned with broader industry trends toward digitalization and sustainability.

- The ‘Smart Undercarriage’: The integration of IoT sensors into undercarriage components is a key area of development. These sensors will provide real-time data on vibration and temperature, enabling predictive maintenance to prevent failures before they occur.

- The Circular Economy: As sustainability becomes a greater focus, the recycling of used pads is becoming more viable. Advanced processes can now efficiently separate rubber from steel, allowing both materials to be recovered. This will eventually support buy-back and remanufacturing programs, turning wear items from a cost into a recoverable asset.

In conclusion, the decision to use advanced rubber track pads is a strategic one that directly impacts a project’s budget, timeline, and risk profile. By selecting the appropriate material and system for the application, and by focusing on the total cost of ownership, construction firms can leverage this technology to improve the efficiency and profitability of their operations in the modern built environment.