Mosquito control for canning factories is essential to maintain a safe and hygienic environment. You must manage these pests effectively because mosquitoes can carry diseases and contaminate food products, risking worker health and product quality.

The best approach to mosquito control for canning factories involves regular inspection, eliminating standing water, and using targeted treatments designed for industrial settings. These measures reduce breeding areas and prevent mosquitoes from entering production spaces.

Implementing a focused mosquito control strategy protects your facility’s cleanliness and ensures it complies with health regulations. Understanding how mosquitoes thrive around canning factories helps you take practical steps before infestations become problematic.

Understanding Mosquito Risks in Canning Factories

Mosquitoes present specific challenges to your canning factory environment. You need to identify what attracts them and the risks they pose to both your products and your workers.

Mosquito-Borne Hazards for Food Production

Mosquitoes can carry pathogens such as viruses and bacteria. These may contaminate the surfaces and materials in your factory, risking product safety. Even if mosquitoes don’t directly transmit foodborne illnesses, their presence indicates poor sanitation or standing water, which could harbor other pests.

Regular mosquito control for canning factories helps limit these risks by reducing the chances of contamination. You should implement monitoring to detect mosquito activity early. This fosters safer food production environments.

Factors That Attract Mosquitoes to Canning Operations

Standing water caused by leaks, plumbing issues, or condensation provides breeding grounds for mosquitoes around your facility. Organic waste and plant materials common in canning factories also attract these insects.

Low airflow zones and shaded areas near loading docks or water storage tanks can increase mosquito presence. Effective pest management in canning facilities includes eliminating stagnant water and maintaining a clean, dry environment to reduce mosquito populations.

Impact on Product Safety and Worker Health

Mosquitoes threaten product integrity by potentially introducing contaminants during processing and packaging. Their presence can damage your factory’s hygiene standards and complicate compliance with food safety regulations.

Beyond products, mosquitoes affect worker health by exposing staff to bites and possible mosquito-borne illnesses. Implementing robust mosquito mitigation in food processing reduces these hazards, protecting your workforce and your factory’s reputation.

Integrated Mosquito Management Strategies

Effective mosquito control for canning factories requires a targeted approach combining thorough monitoring and practical barriers at entry points. This ensures early detection and reduces mosquito presence without contaminating food canning factories.

Mosquito Surveillance and Inspection Protocols

You must establish a regular mosquito inspection for canning operations in Southlake, focusing on indoor and outdoor areas around the plant. To detect breeding early, use ovitraps and larval sampling at standing water sources near the facility.

Daily visual inspections of drains, storage tanks, and waste disposal areas help identify potential mosquito habitats. Mosquito light traps can be used to track activity in production zones but away from food-contact surfaces.

Document findings systematically. This data supports targeted insect control for food canning factories and helps adjust treatment schedules to minimize mosquito presence effectively.

Preventive Measures for Mosquito Entry

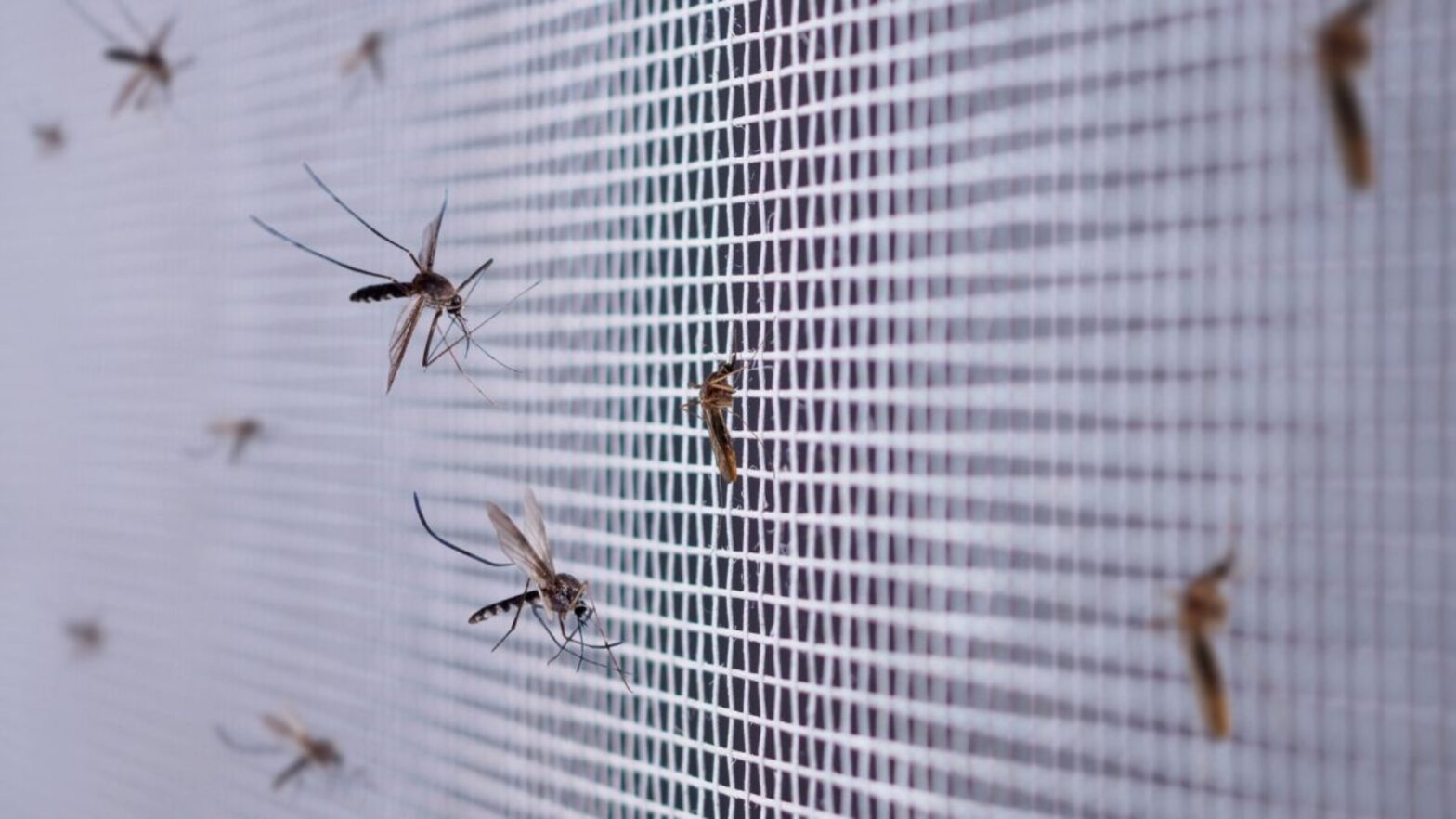

To prevent mosquito entry at canning plants in Southlake, install fine mesh screens on all windows, doors, and vents. Keep doors closed using self-closing mechanisms.

Seal gaps around pipes, cables, and conveyor systems to block access points. Improve drainage and remove unnecessary containers to manage outdoor vegetation and standing water near the facility.

To reduce mosquito attractants, maintain strict sanitation protocols, including frequent cleaning of waste bins and storage areas. Use air curtains in high-traffic doorways for additional protection without compromising workflow.

Commercial Solutions and Best Practices

Effective mosquito control in canning factories requires targeted approaches that address breeding sites, apply appropriate treatments, and involve expert intervention. Solutions must minimize risk to products and comply with health regulations.

Environmental Controls for Canning Facilities

Maintaining a canning factory’s surroundings is crucial to reduce mosquito habitats. Eliminate standing water in drains, equipment, and outdoor containers where mosquitoes breed. Inspect and clean gutters, floor drains, and cooling towers regularly.

Install screens on windows and doors to prevent mosquitoes from entering production areas. Use proper waste management to avoid the accumulation of organic debris, which attracts mosquitoes.

Proper ventilation and humidity control inside the factory also reduce favorable conditions for mosquitoes. Focus on eliminating even small water accumulations, as these provide breeding grounds in commercial mosquito treatment canneries.

Customized Chemical and Biological Treatments

Chemical treatments must be carefully selected to avoid contamination risks in canning operations. Approved larvicides and adulticides must be used in non-production areas and outdoors.

Biological controls, such as introducing mosquito larvae predators or using bacterial larvicides like Bacillus thuringiensis israelensis (Bti), offer safer options for factory mosquito control solutions. These options reduce mosquito populations without harming your facility’s environment.

Rotate chemical classes to prevent resistance buildup. Timing treatments to mosquito life cycles increases effectiveness while meeting regulatory requirements.

Collaboration With Professional Pest Control Services

Working with licensed pest control professionals is vital for effective mosquito control. Experts assess your factory’s unique conditions and implement customized treatment plans.

Professionals from commercial mosquito treatment canneries use advanced monitoring tools and safe chemical applications for food-handling environments. They also provide ongoing maintenance and documentation to support compliance.

Partnering with a specialist ensures you address mosquito problems promptly and thoroughly, reducing downtime and protecting your product quality.

Call Critter Stop at (214) 234-2616 for a free inspection for reliable, humane pest management. Critter Stop is highly regarded for delivering thorough solutions and exceptional customer service, making it a top choice for wildlife and pest removal from your property.