Aircraft maintenance is an integral part of preventing aerial accidents. With so many moving parts and complex systems in an aircraft, it’s easy for something to go wrong in flight. That’s why aircraft maintenance is a highly specialised field that requires technicians to have knowledge of the aircraft, the parts that make up an airplane, and how they function together.

Aircraft maintenance is so essential that many countries have laws and regulations requiring aircraft owners to perform regular maintenance checks on their planes. In addition, aircraft maintenance technicians must also be able to diagnose problems and find solutions to them to keep planes flying safely for years. So, this can be a rewarding career, especially for those who enjoy working with their hands.

Aircraft Maintenance Overview

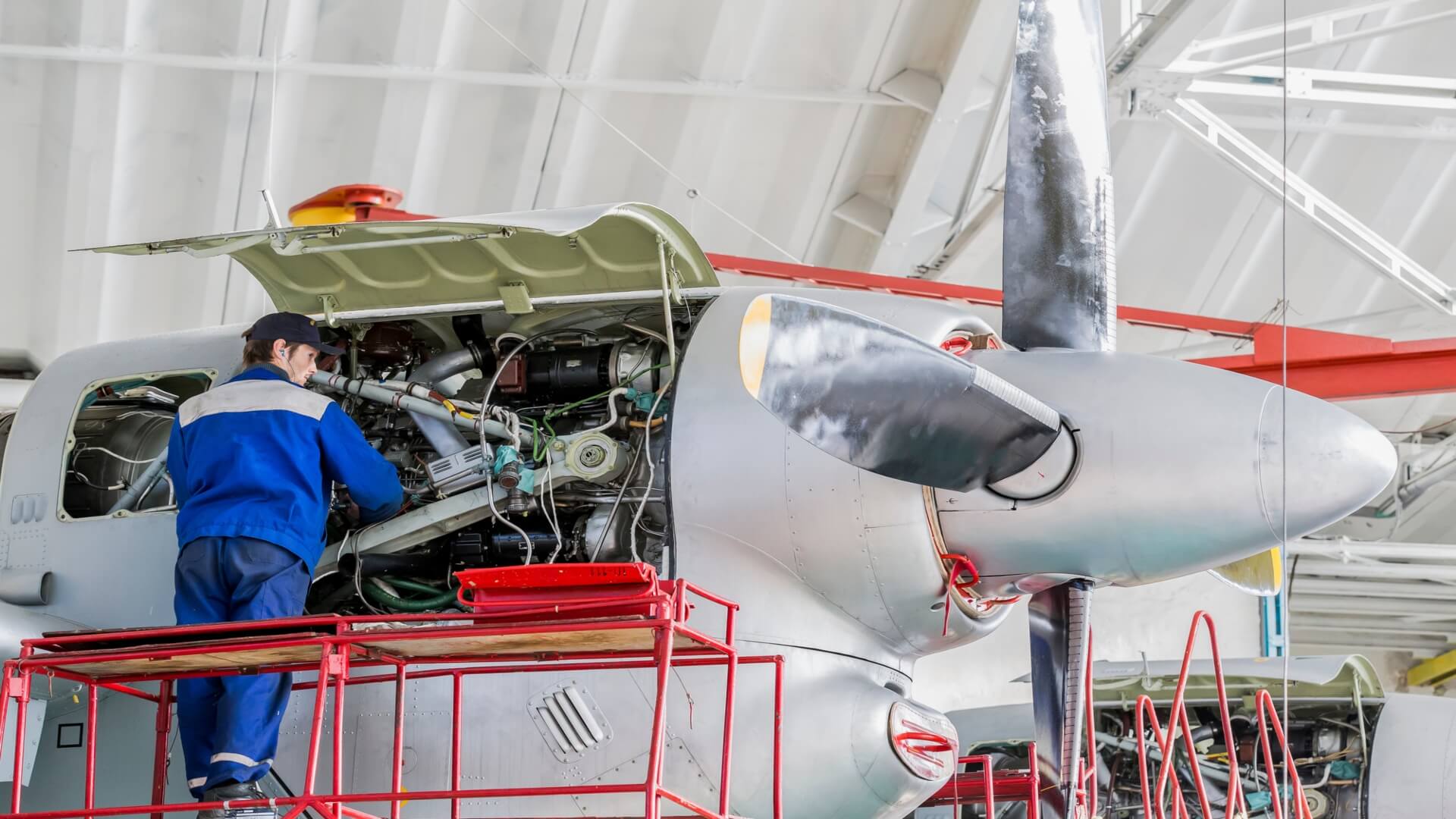

Aircraft maintenance is the process by which aircraft are maintained, repaired, and overhauled to ensure they are airworthy. Maintenance technicians work closely with airline pilots and other aviation professionals to ensure planes are safe for flight. They perform inspection and maintenance such as the aircraft electrical testing, repair any damage like bulb fixing and keep records of their work so that the plane’s maintenance record is always up-to-date.

Aircraft maintenance technicians work on various aircraft, including commercial jets, military aircraft, and small private planes. The job can be physically demanding, requiring technicians to work in small, cramped spaces. It also requires a good deal of manual dexterity and attention to detail.

Types Of Aircraft Maintenance

Some of the most common types of aircraft maintenance include:

1. Depot Maintenance

This maintenance is usually done at a facility where all planes are kept. Airline maintenance facilities, military aircraft hangar bases, or other large airports often have depots where aircraft are repaired and maintained. Aircraft needing major repairs are sent to a depot, and a specialised team of technicians performs the maintenance.

Depot maintenance includes heavy repairs, such as replacing damaged parts, and lighter work, like cleaning and polishing the plane’s exterior. Also, this maintenance requires the most time and resources and takes place at a specialised facility. In addition, depot maintenance may also occur on-site, depending on the airport and the aircraft type.

2. Service Maintenance

This maintenance takes place regularly, depending on the airline’s needs. It includes routine inspections and repairs on aircraft systems, such as the engines, and replacing broken light bulbs and landing gear. Service maintenance usually takes place at the airport and requires a team of technicians with specialized training.

A critical aspect of service maintenance is keeping records of all work done on the aircraft. It helps to ensure that the plane is safe to fly and that all repairs are done correctly. It’s also essential for airlines to keep records because regulators may ask them for proof of maintenance, such as a logbook or certificate of airworthiness.

3. Line Maintenance

Line maintenance is an airline’s regular pre-flight and post-flight inspection of its planes. This type of maintenance is done by trained technicians who work for the airline or an outside company contracted by the airline. Line maintenance aims to keep the plane in good working condition while being used so that it doesn’t break down during flight and endanger passengers.

Examples of line maintenance include troubleshooting, component replacement, lubrication, etc. This type of maintenance is efficiently done quickly so that the plane can get back into service as soon as possible.

4. Base Maintenance

Base maintenance is the type of maintenance performed on an airplane at a maintenance facility after being taken out of service. It’s typically performed by a team of mechanics who work for the airline or an outside company contracted by the airline. This maintenance is done on a plane when it’s not being used and usually takes longer.

Examples of base maintenance include repairs to components that have been damaged or worn out, such as corrosion repair and replacing parts that have reached the end of their lifespan. Base maintenance aims to keep the plane in good working condition so it can be used safely for years to come.

5. Ramp Check

A ramp check is a type of inspection that airliners undergo before they depart. During this process, an airline team member checks the plane to ensure everything is in good working order and safe to fly. An airline will typically have its ramp check checklist, which includes checking the brakes and tires, ensuring all fluids are at the right levels, and checking the security of airplane windows and doors on planes with sliding doors.

Conclusion

Aircraft maintenance is a complex and expensive process. Airlines must take their time when performing maintenance on their aircraft to ensure safety for passengers and crew members, as well as for themselves. One of the best ways to do this is by hiring an experienced team of aircraft technicians who know what they’re doing and can get the job done perfectly.