Whether for personal or professional projects, tools and machinery are often essential. Yet the right gear comes at a price, and sometimes the expense is too much to justify.

If you are feeling hamstrung by how costly certain kit can be, the following tips could save you quite a bit of cash without requiring significant compromises to be made in the process.

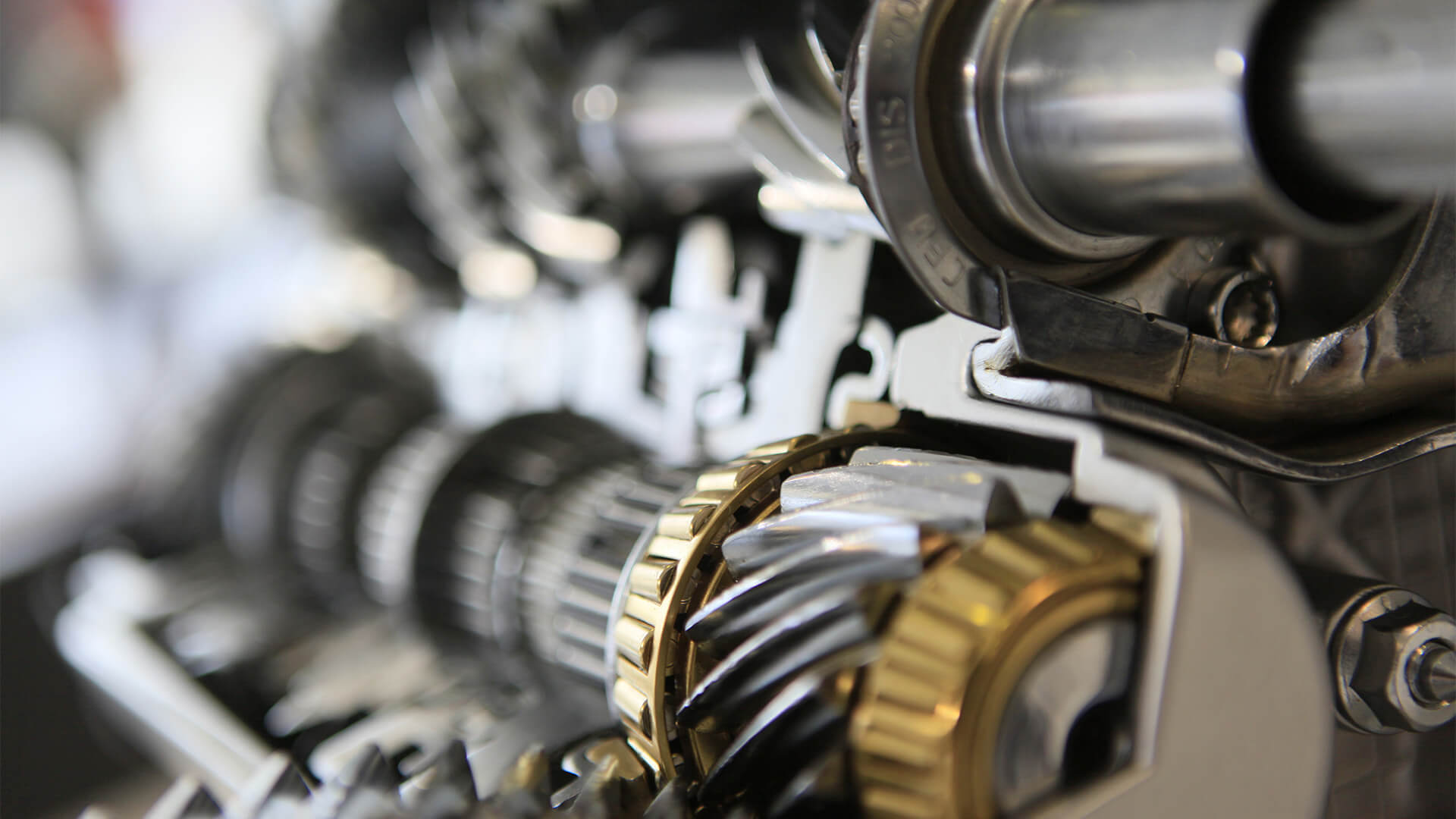

Consider purchasing used machines where possible

If you are only opting for brand-new equipment, then you can’t avoid paying a steep price for the privilege. This is entirely unnecessary since there is a buoyant market for used machines, the best examples of which will be every inch as appropriate for the job at hand as their new counterparts.

For example, a pipe bender is a used machine which is suited to large-scale commercial operations, and second hand models will cost thousands less without sacrificing any functionality.

Obviously, you need to order used equipment from reputable vendors, and also look into the history of the unit in question so that you know whether it has been well maintained. But even with these caveats, going for second-hand tools still makes sense.

Get the timing right

Lots of markets are subject to seasonal peaks and troughs of demand, and this applies to tools and machinery in much the same way as it does to everything from cars to air travel.

This means that sometimes it is sensible to hold off making a purchase until you can do so at a lower-than-usual price point, such as during a sales period.

Black Friday has taken over the world of consumer goods, and yet sales events around this phenomenon are operated in many other markets as well.

Of course if delaying your purchase means hampering your plans and throwing a spanner in the works of your finances, then it might not be worthwhile. But if you aren’t in urgent need of a specific item, your patience might pay off.

Rent, don’t buy

Owning expensive tools outright is not always practical. This is about more than money; if you only need the machine infrequently, it could be far more frugal and strategically sensible to hire it on the fly instead.

This is not just appealing from a savings perspective, but also means that you aren’t stuck with an item that you have to find the space to store. Likewise, if you don’t own it, but merely hire it ad hoc, you are free from the need to worry about maintaining it.

Explore energy costs

The cost of equipment is tied not only to the hardware itself, but also the amount of power it requires to function as intended.

This could mean that running older, less efficient gear is more expensive in the long run than choosing a newer equivalent.

Obviously you need to calculate this carefully and come to your own conclusions based on your own needs and budget.

Make maintenance a priority

Should you be the owner of tools and machinery, maintenance of these assets has to be high on the agenda.

This will of course take time and money in its own right, but if you put in the effort to look after valuable equipment, then this will be repaid over time with improved reliability, as well as a higher resale value when the time comes.

Treating gear as disposable is the worst thing to do since this will invariably lead to bigger bills and less consistency of performance. It could even be a safety concern, so follow all these tips to save money and avoid common snafus.